Fluytec celebrates its 40th year of business in 2019. Their longevity is down to not only being a market leader in developing specific prefiltration technology but also manufacturing and marketing the systems they produce.

In a recent article for The International Energy Agency, energy analyst Molly Walton commented:

“Countries in the Middle East already have some of the lowest water availability levels on a per-capita basis in the world. And economic and population growth in the region are set to increase demand for water over the coming decades, a period during which rising temperatures in the region could impose further constraints on water supply.”

One company that is helping to tackle this considerable and often ignored issue, is Fluytec Filtration Technologies.

Based near Bilbao, Spain, the company has over 40 years of experience in designing and manufacturing equipment used in the desalination process, which produces fresh water for irrigation, industrial and municipal purposes.

They have supplied equipment to every corner of the globe and have spent more than 20 years working in the Middle East.

Pedro Otegui Martinez is the Director General of Fluytec and, as a trained engineer, he has spent most of his working life involved in a number of companies based in and around the industry, and over eight years at Fluytec. He described his company’s main field of expertise.

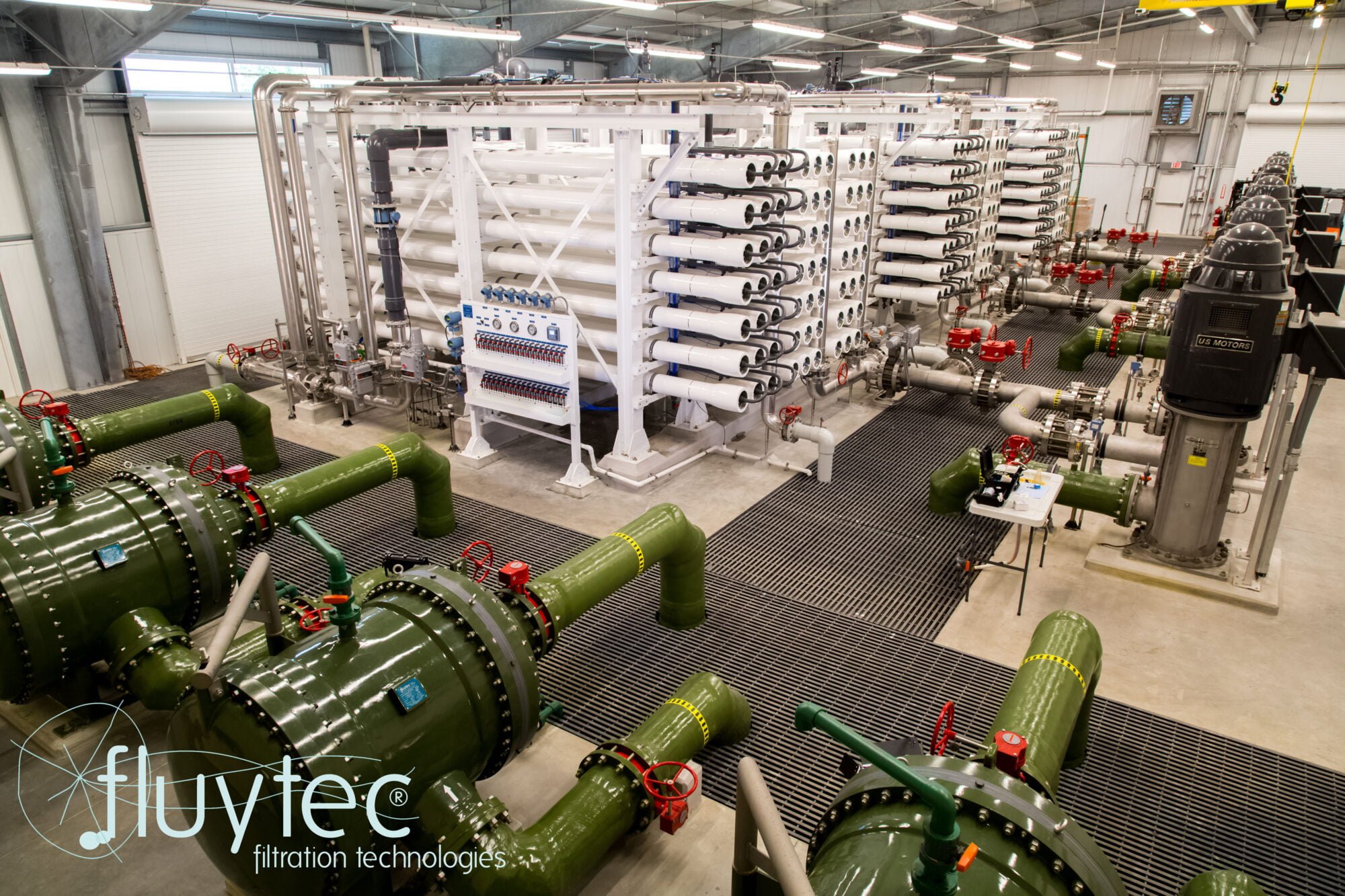

“Fluytec operates in the field of design and manufacturing of filtration technology, predominantly focused on the pre-treatment of Reverse Osmosis (RO) installations. We design, manufacture and supply pre-treatment systems for RO facilities, including cartridge filtration, ultrafiltration, self-cleaning strainers and static mixers, all built in a wide spectrum of materials. We also offer tailor-made filtration products and services for special individual needs or applications.”

Reverse osmosis is a water purification technology that uses a partially permeable membrane to remove ions, unwanted molecules and larger particles from drinking water. With many countries in the MENA region dealing with incredibly salty water, that can suffer from aggressive algae growth, this kind of water treatment is prevalent in the area. In fact, over 70% of desalination plants throughout the world are found in this region, located in the UAE, Saudi Arabia, Oman, Bahrain and Kuwait.

Pedro believes that, although there is a great deal of competition out there, Fluytec has quietly carved itself out a solid reputation in the marketplace.

“Fluytec is a company that operates worldwide and although our niche market is relatively small, we remain one of the best known in our sphere, so being a major player in our field is a plus,” Pedro believes.

“We currently employ around 100 people and I know everyone who works for me. Because of our size, it is very easy to quickly implement new plans and ideas and you get to see the results of your decisions very quickly. I like that agility, where we can immediately adapt to new ideas or processes.”

With his background in engineering, specifically in membrane-based technologies, Pedro was initially hired by Fluytec to develop and expand their technology and help manufacture new products. As he explained, this is where Fluytec stands out from the crowd.

“We have two types of competitors. There are engineering companies that are connected to filtration who, like us, focus on developing new products, and who are also looking for new applications. However, these companies are typically not manufacturers – which we are. When we manufacture, we not only produce the product, but we also learn about the materials we are using, which are often extremely technical. We work with composite materials that are made up of four or five different components and need to go through a number of different manufacturing processes in order to produce one final material.”

Over the last few years, Pedro and his team have focused on developing new design and manufacturing capabilities, aiming to create products that have an added value. However, this obviously takes time and money and Pedro admits there are many challenges involved.

“We have not purchased any other companies but are trying to grow organically and have employed our own engineers to develop our products. Financing these developments is a huge undertaking and takes a great deal of time and, because of our limited capital, can be a slow process. But I firmly believe our patience will pay off in the long run and we have some exciting developments in the pipeline.”

In Portugal, Fluytec has invested in the development of their own plant to increase their manufacturing capacity by 300%, but they are also quick to create partnerships with other companies in order to maximise their operation, and outsourcing is always a possibility, as Pedro explained.

“Sometimes, if we happen to find very good, reliable, supplier we have elected to halt our own production because another company can do a better job or produce the same item at a more competitive cost. It is all about operating efficiently and our technicians are constantly looking at these opportunities to ensure we always weigh up the best options as to whether we should integrate or outsource.”

Fluytec is also happy to partner on new designs with other suppliers, in order to achieve their goals…

Click here to read and download the full article